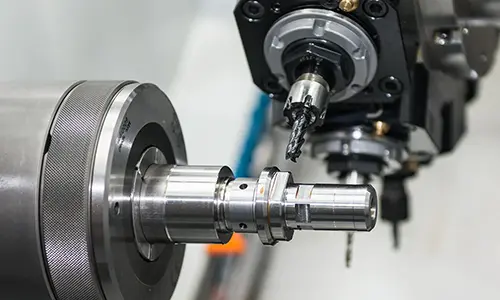

CNC turning is one of our core services, which involves the manufacturing of materials through rapid rotation and the removal of excess material using a fixed tool. This turning process allows for the production of precise, turned parts with varying levels of complexity. Thanks to our modern CNC machines, we are able to carry out even the most demanding projects, delivering components of the highest quality and speed.

At Perlik Aluminium, we offer metal turning for various industries, including the automotive, medical, and construction sectors. Our CNC milling turning process allows us to machine metals such as aluminium, steel, and copper with the utmost precision and repeatability. We provide both single-piece and mass production, making our turning services a flexible solution for diverse industrial needs.

Turning metal is an ideal solution for the production of parts that require precise surface machining. The turning process ensures smooth and accurate shapes, which are critical for many engineering applications. Our machining workflow is carefully planned in steps to guarantee efficiency and quality at every stage. Thanks to our advanced machinery, we can execute projects of varying difficulty and adapt to the specific requirements of our clients.

As part of our services, we also offer metal turning, covering a range of materials from lightweight aluminium alloys to more demanding materials such as stainless steel. Our CNC machines ensure consistently high machining quality, minimize errors, and guarantee repeatability in large-scale production. As a result, our turning services are highly trusted by customers who require precise and reliable machining.

Wersja polska

Wersja polska Deutsche Version

Deutsche Version